Sheet metal - thin

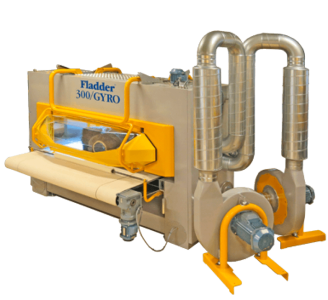

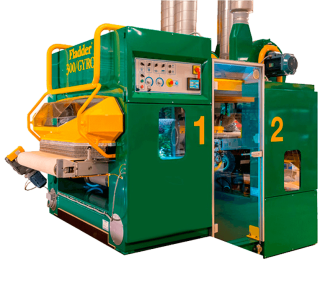

FLADDER DENMARK A/S offers advanced deburring machines and tools capable of handling various materials and components, including sheet metal.

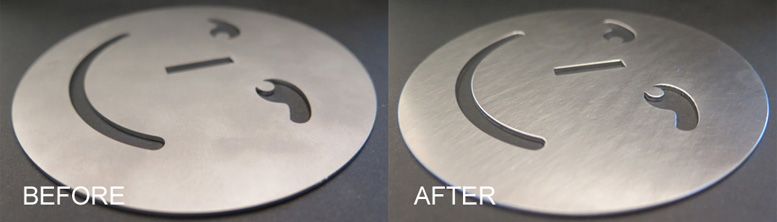

Sheetmetal, whether laser-cut, punched, or sheared, often have sharp edges that can pose a risk of cutting injuries during handling and use. Additionally, sharp edges can result in scratches and assembly issues, as well as problems with insufficient coating thickness during painting.

FLADDER® deburring systems provide optimized deburring processes that facilitate easier and faster deburring of sheet metal parts. Our dry deburring technology grinds without damaging surface coatings or film and avoids critical surface heat.

Furthermore, FLADDER® deburring systems ensure controlled edge rounding and uniform quality throughout the component, even with variable thicknesses and complex contours. Our flexible deburring tools can also handle components with grooves and other irregularities.

FLADDER® deburring systems can effectively handle typical sheetmetal components, enhancing both safety and quality of the component, while also improving adhesion during painting or bonding.