Technology

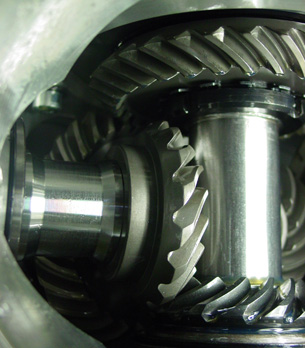

The gear head - technological unique - the "heart" in our machines for deburring, surface finish, denibbing and lacquer sanding.

The gear head is a very solid construction.

The housing of aluminium has outside cooling ribs and inside room for the specialcut toothed wheels in chrome vanadium steel.

The force from the main motor is transferred directly to the 6 spindles.

The construction proved to be perfect in our efforts to achieve the perfect deburring technology, wood finish sanding and lacquer intermediate sanding technology.

The new deburring technology has also gained ground in many companies.

Efficient processing of the workpieces

- oscillating and rotating gearhead with 6 counter rotating spindles

The gear head with the main motor and rotatin motor is mounted on a scissor suspension frame.

The scissor is equipped with special hardened, grinded wheels.

It makes it possible to create the linear, oscillating movement across the conveyor belt.

This - combined with the in pair counter rotating spindles - results in uniform workpieces and uniform wear of the tools.

To simplify the operation of the machine the 4 movements are synchronized 2 by 2.

Technology based on the centrifugal force

The pressure towards the workpieces are created by means of the centrifugal force, specifically through regulation of the rpm.

The FLADDER® technology is a non-aggressive system.

The abrasive cylinders are flexible tools.

It means that besides flat workpieces also bended, shaped and 3 dimensional workpieces can be processed.