Fladder® sanding

- the way to a better finish

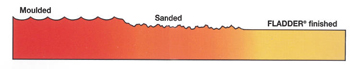

It is a well-known fact that a wooden surface becomes rough after sealing.

The reason for this is that fine fibres are created by ordinary wood sanding procedures, for instance using a widebelt sander.

Because of the pressure of the abrasive material against the surface, the wood’s fibres are severed, resulting in microscopic fibres creating a ’fuzzy’ surface.

During the following sealing process, tension is generated in the fibres causing them to rise, and thereby giving the surface a rough feel.

The presence of these fibres must be minimised or efficiently removed before or after the sealing process.

The solution is to use the FLADDER® sanding system - an innovative sanding method based on sanding principles which are fundamentally different from those of traditional sanding methods.

Rather than sanding with a constant pressure against the surface, the FLADDER® sanding system is based on a principle by which the sanding aggression is created by the sanding tool’s rotating speed.

FLADDER finishing is a non-aggressive type of sanding which removes the fibres without creating new fibres, preserving the part’s dimension

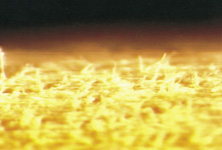

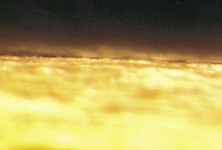

Figures A and B show a wooden surface sanded in the normal way before and after sanding with the FLADDER® sanding system.

A: Before Fladder® sanding B: After Fladder® sanding

Fladder sanding- provides significant benefits:

● Up to 30% reduction in sealer/primer consumption

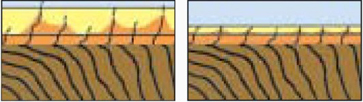

The figur below shows the difference between a normal, sealed surface and a surface sealed after a FLADDER® finishing.

On the FLADDER® finished surface, the amount and length of the fibres are reduced.

This means that

- less sealer is required to effectively seal the surface,

- less sanding is required, and

- the surface becomes more uniform.

Normal sealed surface Sealed surface after Fladder® finish.

● Sharp edges are rounded slightly.

Sharp-edged parts often cause problems in connection with sealing or sealer sanding.

The sealing layer on sharp edges is very thin, and as a result the sanding often penetrates it.

Figure D below shows a profile with sharp edges.

On the surface treated with FLADDER® finishing, the edges have been rounded slightly, but not so much as to cause the part to lose its definition.

As a result, the sealer is able to better enclose the edge, and the risk of sanding through has thus been minimised.

This problem occurs most often on stained surfaces.

● Stain is more uniformly absorbed.

The different fibres on a sanded surface do not always absorb stain uniformly. The look of the surface vary in areas where the stain appears darker.

With a FLADDER® finish sanding the material is processed in such a way as to open the wood’s surface.

This makes the stain penetrate more evenly into the surface and improves the wood’s structure.

This is shown in the Figure below.