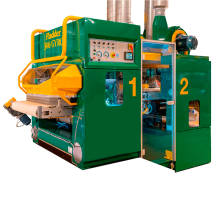

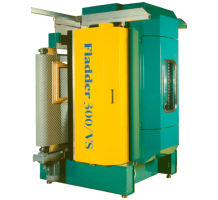

FLADDER 300/GYRO HIGHSPEED

Using grinding tools at higher speeds.

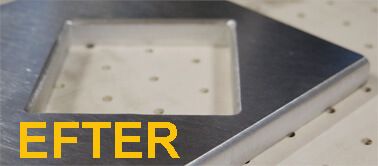

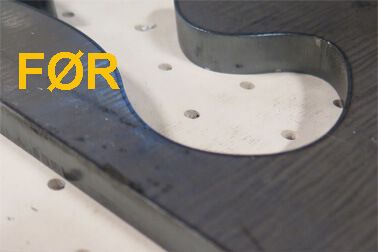

FLADDER® 300/GYRO Highspeed has been optimized for deburring of the edges with substantially greater rounding than seen before.

The ”Highspeed” name indicates, that the process is based on using the abrasive tools with higher speed.

It is common knowledge that a grinding material has a certain cutting speed at which the material works best.

The ideal cutting speed is often found at 30 m/sec or higher. However, there are many technological challenges in being able to work with the necessary, higher revolutions and it requires a perfect interaction between tools, spindles and the machine's construction:

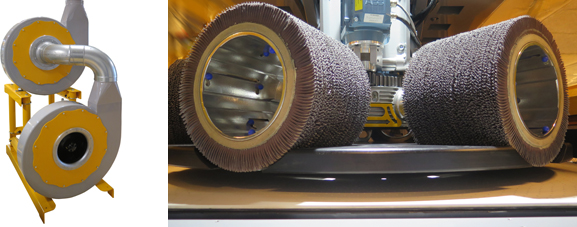

A new type of the FLADDER® abrasive cylinders are manufactured with a high density of abrasive material, but still with the flexible properties needed to create a uniform result on all edges.

The use of our patented lock-itTM spindles means elimination of harmful vibrations from the tools during the “highspeed” process.

In order to ensure that items are held during the process, the machine is equipped with a powerful 2-step vacuum system combined with mechanical support.

Furthermore, the machine is equipped with sensors that electronically monitor the machine's operating state and intervene in case unacceptable vibrations are detected. It reduces damage to the machine and the items.

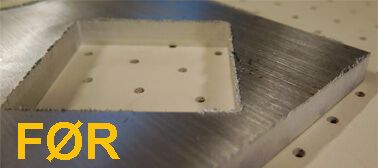

For manufacturers of mild steel, there is an added benefit of using the machine: In addition to rounding the edges, the oxide layer on the edges is also removed - on items up to 10mm thick.

FLADDER® 300/GYRO Highspeed is equipped with a powerful gear head mounted with 6 cone spindles for mounting of the Lock It spindles.

The spindles are in pairs counter rotating while the complete gearhead is performing an oscillating and rotating movement over the surface of the work piece.

The central head carrying the tools is an extremely strong and compact unit.

The control panel including a touchscreen ensures an easy and manageable operation of the machine.

The machine body is powder coated and solid built with strong shields that offers a perfect view of the process through the large windows.

Uniform finishing of work pieces and uniform wear of the tools:

Energy friendly

Fladder Danmark is focused on saving energy.

Therefore most motors in the machine are as standard controlled by frequency inverters.

Technical data

-

Working width:1300 mm

-

Infeed speed:0,5 - 3,5 m/min.

-

lock-it spindel:6 x 200x250 mm

-

Machine width:2300 mm

-

Max. Work piece width:1300-1500 mm

-

Max. workpiece height:100 mm

-

Max. power consumption:35,0 kW

-

Max/min fuse:80 A

-

Net weight:2300 kg

-

Total height:2210 mm

-

Total length:2070 mm

-

Voltage:3 x 400/500V